PMI Foam

We are sourcing and manufacturing parts using this foam core material

Highest Performance Sandwich Core Material. Next only to Honeycomb

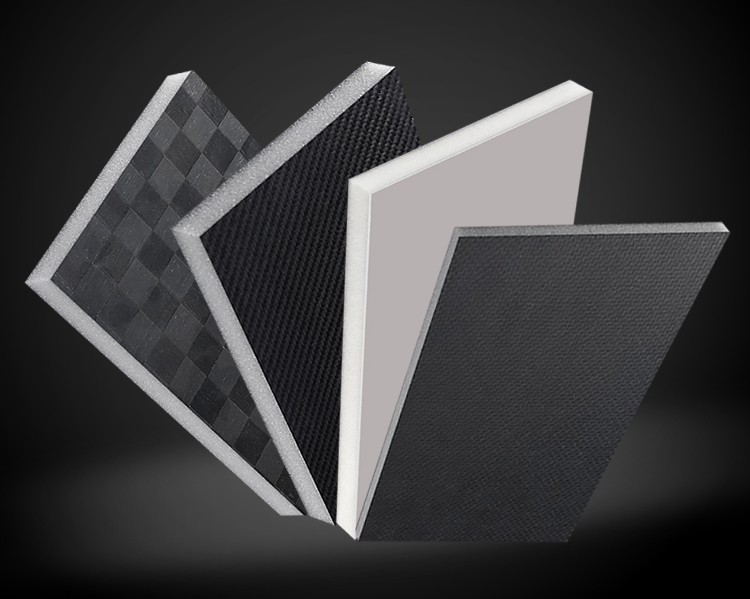

Closed Cell Structure for minimal resin uptake during composites layup process

Offers Highest Specific Strength, Specific Modulus, Compressive Resistance, Creep Resistance, for a given density

Other than metallic Aluminum and SS Honeycombs, PMI foam is the only polymeric core that are rated up to V1 – UL94 Flammability test. Making it suitable for use in Railways and safety critical systems

We offer range of PMI foams for use in various applications

PMI Foam Available Grades

FR

– Fire Resistant Grade

– Self Extinguishing Grade

– Suitable for Railways, Marine Applications, Aviation Interiors

– No Galvanic Corrosion

– Self Extinguishing Grade

– Suitable for Railways, Marine Applications, Aviation Interiors

– No Galvanic Corrosion

IH

– General Purpose Foam

– Suitable for use in Automotive, Shipbuilding and Sports Equipments

– Suitable for use in Automotive, Shipbuilding and Sports Equipments

HF

– Designed for Antenna Applications

– Extremely Low Dielectric Constants

– Favourable Transmission Properties

– Used for Radomes and Mammography Plates

– Extremely Low Dielectric Constants

– Favourable Transmission Properties

– Used for Radomes and Mammography Plates

RS

– Designed for Vacuum Infusion and Resin Transfer Molding

– Cell Size is smaller to reduce the resin uptake

– Can be easily thermoformed or CNC Machined

– Available in complex 3D molded shapes

– Cell Size is smaller to reduce the resin uptake

– Can be easily thermoformed or CNC Machined

– Available in complex 3D molded shapes

WH

– Designed for Autoclave Processing, RTM and VARTM Process

– Can be Thermoformed, CNC Machined or molded into 3D Molded Shapes

– Can be Thermoformed, CNC Machined or molded into 3D Molded Shapes

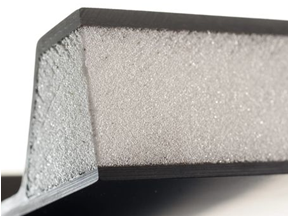

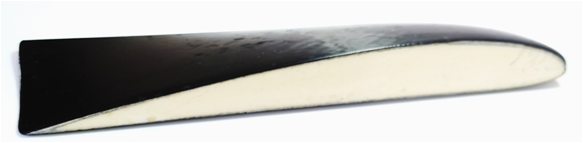

Custom Shapes in PMI Foam Sandwich Construction

- High Impact Resistant Profiles

- High Bending and Torsional Stiffness and Rigidity